Innovation Lab gives Logoplaste a reliable way share product designs

Joel Monteiro

- Client Logoplaste

- Role Portals & Collaboration

- Year 2022

The client:

Logoplaste is a global value-added service provider and producer of rigid plastic packaging for well-known fast moving consumer goods companies in the food and beverage, cosmetics, personal care and household industries. Founded in 1976, the company is the pioneer in the wall to wall, embedded manufacturing model, significantly reducing CO2 emissions by eliminating transportation of empty bottles and secondary packaging, improving the overall environmental impact across the entire supply chain. Logoplaste currently manages 63 plants in 16 countries.

The challenge:

The Logoplaste Innovation Lab team used to send packaging designs via email to plant managers all over the world. The plant manager would then pass the designs to production, but the documents would only be stored in their email inbox. If for some reason, the plant manager was replaced, the new plant manager would have to request the same designs. Logoplaste’s Brazilian branch developed a document repository on the Classic SharePoint Online Experience where they shared design documents, and the company saw the potential of implementing a similar platform that could serve Logoplaste’s global operation. Due to time and resources constraints, they decided to seek a partner to develop it.

The solution:

Logoplaste got in touch with our team to develop a design repository where design documents could be shared with the company’s plants, regardless of where they were located. In addition to being global, this platform should also be reliable and flexible, adjusting to the user’s permissions.

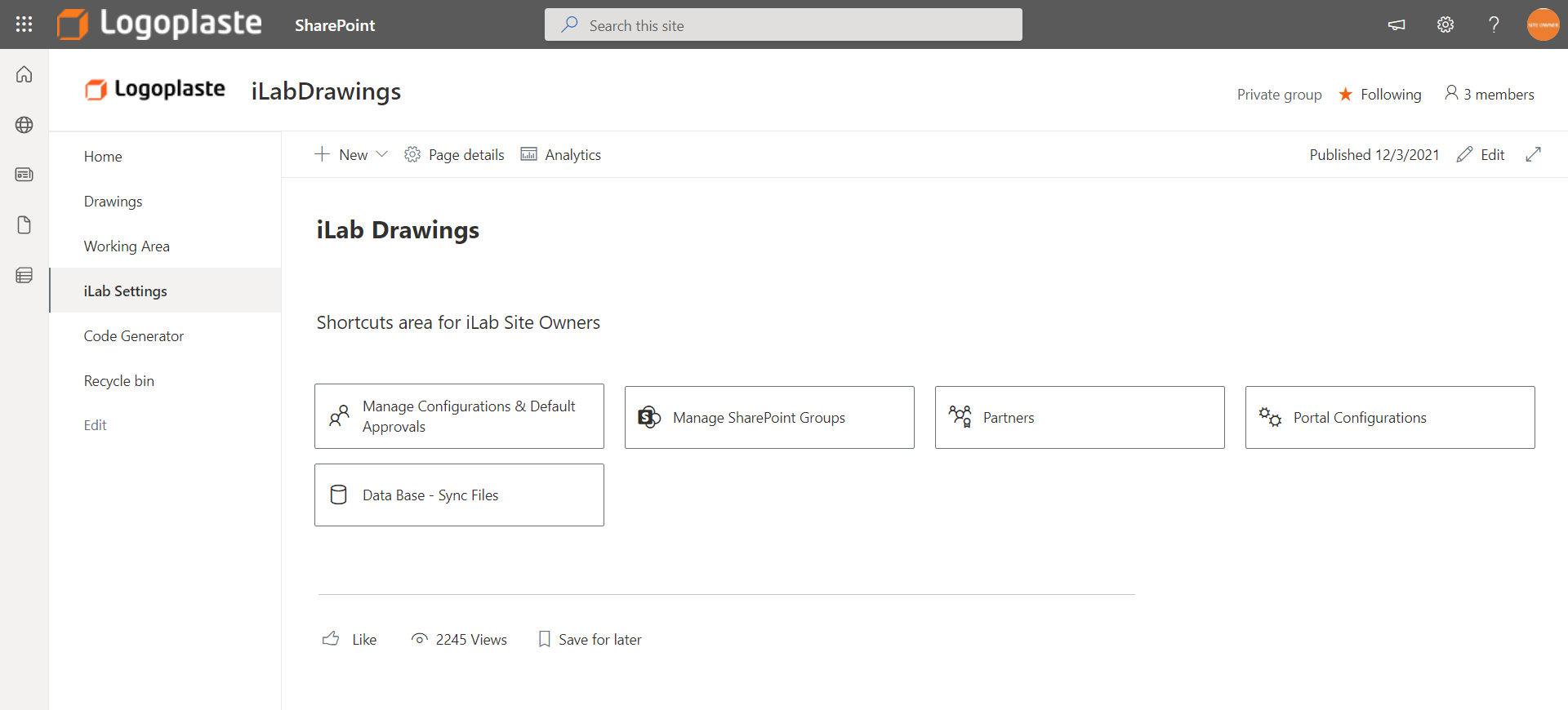

Named Logoplaste Innovation Lab Drawings repository, Logoplaste’s new platform is a SharePoint Online portal developed by the team at DevScope that uses Power Automate to ensure designs and users are always in sync.

Whenever someone joins the company, Logoplaste grants them access to the Innovation Lab Drawings repository, and when someone leaves, access is revoked. If a user moves to a new plant, their access also changes. The new portal guarantees that the designs currently in production are available to anyone who needs access to them, from the quality department to the personnel operating the machines. This system ensures that they are always using the most recent design, which was often a problem in the past. Despite having the latest designs available on their server, sharing was done by email, so the question of whether the factory was working with the correct design or not lingered.

With this new process in place, designs are only available in the Innovation Lab Drawings repository, and plants must only produce what’s there. If a design is discontinued, the Logoplaste Innovation Lab is informed to remove it, and all design change requests trigger an approval process on Power Automate that, ultimately, replaces the active model. This system ensures that the Innovation Lab Drawings repository is the only place where the latest designs are available and completely removes the need for email exchanges during these processes.

Results:

The Logoplaste Innovation Lab team got in touch with each plant manager to show them the new SharePoint portal, explain its features and collect the designs currently being produced at each location that should be on this new platform. Local staff was trained, and the correct designs were uploaded to the Innovation Lab Drawings repository.

“We can now look at a production unit or a country and know exactly what’s being produced.”

– Rudiney Souza, CAD Manager at Logoplaste

Before using the Innovation Lab Drawings repository, the Logoplaste Innovation Lab verified the active designs with each plant and checked what was being produced on SAP, only to realize that they weren’t always producing the correct design. With its new SharePoint Online portal, the company can now look at any plant and know for sure what’s in production. They can also consult their database more simply, apply filters and collect information faster than ever when working on a new project.

Technologies used: